What is Plating?

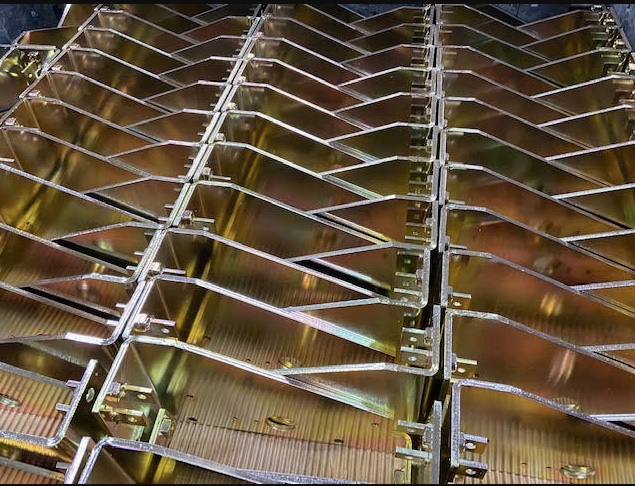

Metal plating is a process whereby a metallic substrate, usually a tool or machine part, is coated using a metallic layer typically consisting of zinc, cadmium, chromium, nickel, gold, or other metals. These coats can come with a single metal plating or a mixture of metals to create a specific plating property.

The process of plating is crucial as it maintains the integrity of the base metal while also creating a protective barrier against corrosive elements. Nickel plating, electroless nickel plating, and silver plating are several forms of metal plating that can improve durability and corrosion resistance.

The surprisingly simple process of metal plating is usually achieved through two of the most commonly used methods – electroless plating and electroplating. Both of these methods achieve the same durability objectives but through different steps. Through a controlled process of electrolysis, workers transfer metals from an anode to the metallic part being plated – or the cathode.

The second method, while more complicated, uses a chemical reaction to apply a plating coat and doesn’t require a power source. Electroplating and electroless plating each have pros and cons, but the cost and end result are the primary reasons they are the most commonly used metal plating methods.

Applications of Metal Plating

Plating is used in various industries, often to improve the integrity of weak metals and make them less vulnerable to damage and environmental effects. The electrical and aerospace industries require intense or specialized plating to increase the metal’s wear resistance and protect the metal parts from corrosive exposure, high voltages, or even extreme elements.

Why Does Plating Matter and Why Does Partnering With a Quality Plating Company Matter?

Metal coating solutions are essential since they provide corrosion resistance and damage protection while increasing machine efficiency and maintaining the integrity of your application. They can also improve conductivity and lubricity on metallic materials, leading to seamless operations.

However, you need a reliable supplier to ensure the plating materials and services are of the highest quality, and this premium service is exactly what you get when you work with Monti. Below are three essential qualities to consider when selecting a plater:

1. Short Turn-Around Times

This is one of the attributes that distinguishes Monti from other platers in the market. When you book a plating service with us, we move swiftly to acquire the necessary materials to ensure your superiorly plated parts are delivered within 3 to 5 business days. This is a much shorter turn-around time than what is offered by our competitors, many of whom take up to two weeks to complete the plating process. Our goal is to cause as minimal of a disruption to your operations as possible, increasing efficiency and profitability.

2. Durable Corrosion Protection

The last thing you want for your machinery is poorly done metal plating, which will necessitate a rework after a short period of time. At Monti, we have a team of experts who perform the plating tasks professionally while ensuring durability and optimum efficiency.

Our plating process begins by helping you choose the best plating method for your machinery such as silver plating, tin plating, yellow and clear zinc plating, and nickel plating. This is because, even when professionally installed, low-quality materials will peel and fall off, leaving plating open to oxidation and corrosion.

The other downside of low-quality plating materials is that they can have longer lead times since they were poorly processed from the beginning. This inevitably leads to an inefficient, back-and-forth cycle between the manufacturer and supplier resulting in costly and delayed timelines.

3. Consistency and Reliability

As a business owner or manager, you want your business to remain operational throughout the year with minimal interruptions. By choosing a reliable supplier or contractor, you can ensure that the metal plating process does not become a hindrance to your machinery or organizational goals.

At Monti, we have years of experience providing high-quality plating services to various players in the electrical and automotive industries. Since 1971, we have worked to master the art of metal plating and material selection for various industrial applications. This allows us to meet the specific needs of a diverse set of customers in many different industries.

Our professionals have been rigorously trained to perform high-quality metal finishing services using all types of plating materials including tin, silver, chromium, chromate, and many others. The other benefit of working with Monti is our consistency in delivering quality services. Our technicians will do everything within their power to ensure your job is completed properly the first time to avoid rework and subsequent delays.

Monti Incorporated: The Premier Plating Partner

Undoubtedly, metal plating is an essential process, not only for the electrical and automotive industries, but also for other sectors in which metal parts are exposed to highly corrosive elements. It helps to protect these parts thereby enhancing efficiency and productivity.

However, as a business owner, you need to find a reputable supplier to provide the highest quality plating parts and services without causing significant interruptions to your business operations. With Monti as your metal plating partner, you will save time and money without sacrificing quality. Contact us online or give us a call today to get quality solutions to all your plating needs.