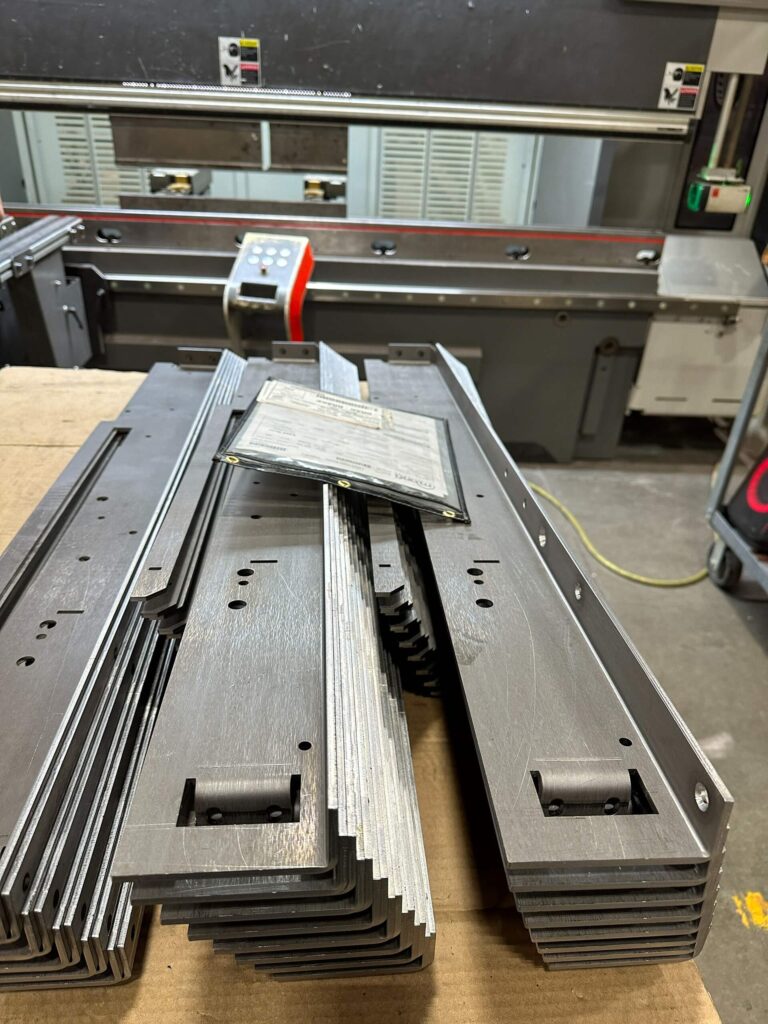

Utilizing a broad array of fabricating machinery, we offer sheet metal fabrication services that include Prototyping, Repair, Retrofit and Production in individual parts to large weldments.

For the repair industry, we are able to reverse engineer damaged or worn out parts and assemblies or fabricate from hand sketches to get electrical gear back in operation in hours rather than days.

For OEM customers, we have the expertise to prototype new designs and suggest areas where materials and labor can be saved. Should the product be introduced to market we can supply parts in limited quantities and then ramp up to high production as product sales increase.

We have the in-house capability of building and running complex progressive dies when volumes and part configuration justify the initial tooling charge

We work with many Materials including:

- Low, Medium and High Carbon Steel

- Copper

- Stainless Steel

- Aluminum

- Brass

Sheet Metal Fabrication Capabilities Include:

3 Fiber Lasers:

4.0 kw Fiber

6.0 kw Fiber

10 kw Fiber

FMS Cells:

Handle 5’x10′ Sheets

2 CO2 Lasers -2,500 watt

13 CNC Press Brakes:

Up to 250 Ton w/ 12′ bed

9 CNC Turret Punch Presses:

Punch & Forming

2 Water Jet Cutting Machines:

Cut almost any material

13 Stamping Presses:

From 45 to 440 tons with coil feeds

3 Wire EDM:

High precision metal cutting

3 Hydraulic Shears:

Cut-to-Size

Material Sales:

Need material?

Welding & Brazing:

Mig, Tig, and Robotic

Secondary Process:

Plating & Powder Coating