As our equipment list attests, Monti Inc. invests in the most productive and up to date machinery. This constant push to find ever more efficient machining processes has allowed us to drastically reduce cycle times, reduce WIP, reduce lead times and ultimately reduce part costs to our customers. Monti Inc. has a full range of capabilities including Vertical and Horizontal Multi- Axis Machining Centers, Machining Cells, automatic part orientation and inspection by the machining center, 2, 3 and 7 axis Turning Centers from Swiss style to large high horsepower machines.’

CNC Milling

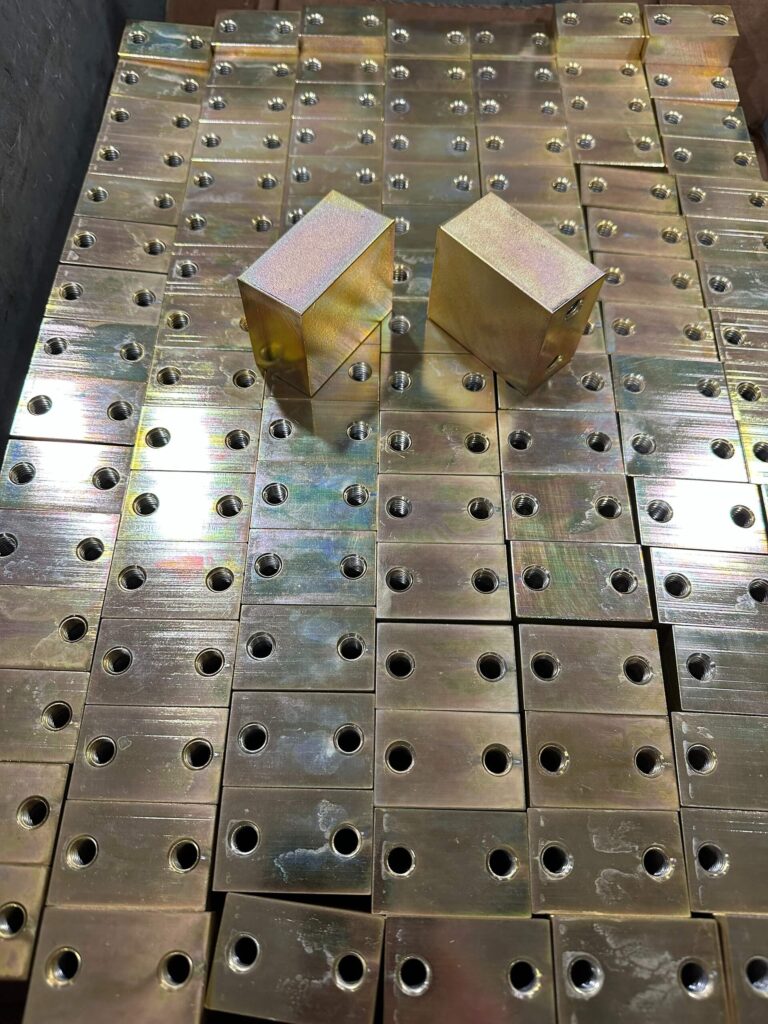

Monti Inc is proud of the capabilities of its milling department which utilizes a combination of 27 Horizontal and Vertical Machining Centers. Our horizontal spindle machines have the ability to load either two or six pallets allowing for up to 24 different work fixtures and running unattended throughout the night. Our vertical spindle, 3 and 4 axis machines, have travels ranging from 16” x 32” to 60” x 120”, we have dedicated high speed spindle machines for non-metallic materials and heavy duty, high horsepower machines to aggressively cut steels. One specialized 4 axis machine is even capable of machining five sides of a 96” long part. To efficiently machine electrical insulation we have 5 CNC routers, these large machines have the capacity to process 5’ x 10’ sheets with high feed rates and quick load/unload vacuum tables.

CNC Milling Capabilities Include:

- Vertical and Horizontal machining centers

- 3, 4 & 5 Axis machining

- Hold tight tolerances on many different types of material

- Vertical mills and routers with travels of 5’ x 10’

- Ability to import part files and automatically nest parts

CNC Turning

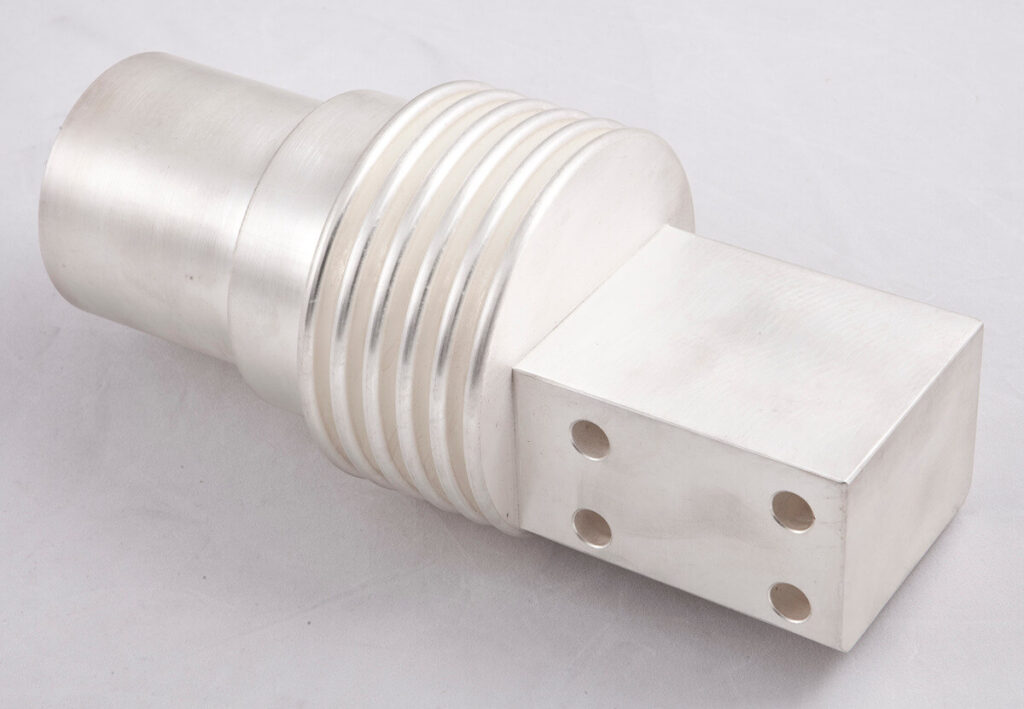

Monti Inc has the latest CNC Turning Centers including 2, 3, 5 & 7 axis machines, complete with live tooling and magazine bar feeders. Utilizing a 5 axis mill/turn multitasking machine allows us to completely machine complex parts up to 20” diameter. Our 7 axis Swiss Style machines allow us to run highly complex, small diameter parts unattended from multiple 12’ long bars. These machines give us “in house” capabilities to manufacture parts required in cabinets and frames produced in our Fabrication Department. A specialty at Monti is the manufacture of copper Stud Assemblies, without our large, high horsepower CNC lathes we would not be able to turn the complex studs from 1” to 6” diameters and up to 29” long.

CNC Turning Capabilities Include:

- 2, 3, 5 & 7 Axis CNC Turning Centers

- Mill-Turn 5 axis multitasking center

- 7 Axis Swiss Type Turning Center w/ 12′ bar feeder

- Hold tight tolerances on many different types of material

- Can machine parts as large as 20″ in diameter.