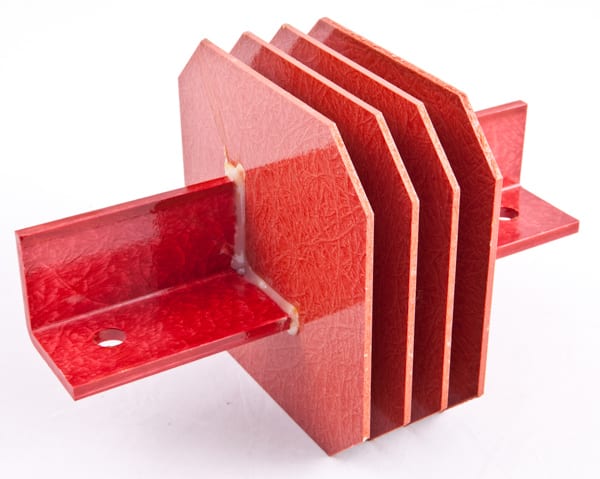

Monti Inc. machines and fabricates Electrical Insulation from a broad range of materials with differing characteristics that can satisfy specific performance requirements. From rigid, high temperature materials to thin flexible films Monti Inc. can deliver your most demanding electrical component parts.

The least expensive fabrication technique for thin materials is punching. Low volume rigid parts are nested and run on our Turret Presses, for higher volume parts that justify hard tooling we will design and build a die to run on one of our Stamping Presses. Flexible materials can be cut by steel rule dies on high production hydraulic presses. Thicker parts that require machining are run on one of three routers or twenty-seven milling machines, including multi-axis 5 sided machining of parts up to 96 inches long. For intricate 2 dimensional work we have the option of running these parts on one of our two Waterjets, these machines have the ability to cut almost any material up to 6 inches thick. Our lathe department has two, three and seven axis lathes to turn the simplest to the most complex parts complete without secondary operations.

Typical types of insulation:

GPO-1, GPO-3, G3, G5, G7, G9, G10, G11, SG-200, XX Paper, Canvas & Linen Phenolics, Valcunized Fiber, Formex, Lexan, Nylon, Teflon, to name a few.

Insulation Machining & Fabrication Capabilities Include:

10 CNC Turret Punch Presses:

Punch up to .25″ thick plastic

13 CNC Press Brakes:

Up to 250 Ton w/ 12′ Bed

30 CNC Mills:

3, 4 & 5 Axis high speed milling

10 Stamping Presses:

Low and high volume

27 CNC Milling Centers:

3 & 4 Axis high speed milling

3D Machining Capable

3 CNC Routers:

63” x 145” Travels

CAD/CAM Processing

Nesting capable

8 CNC Turning Centers:

2, 3, 5, & 7 Axis Turning w/ live tooling

2 Water Jet Cutting Machines:

Cut almost any material

Material Sales:

Need material?

Assembly Operations:

Staring, Riveting

Combining components and hardware

Secondary Process:

Silk screening

Varnishing

Kitting