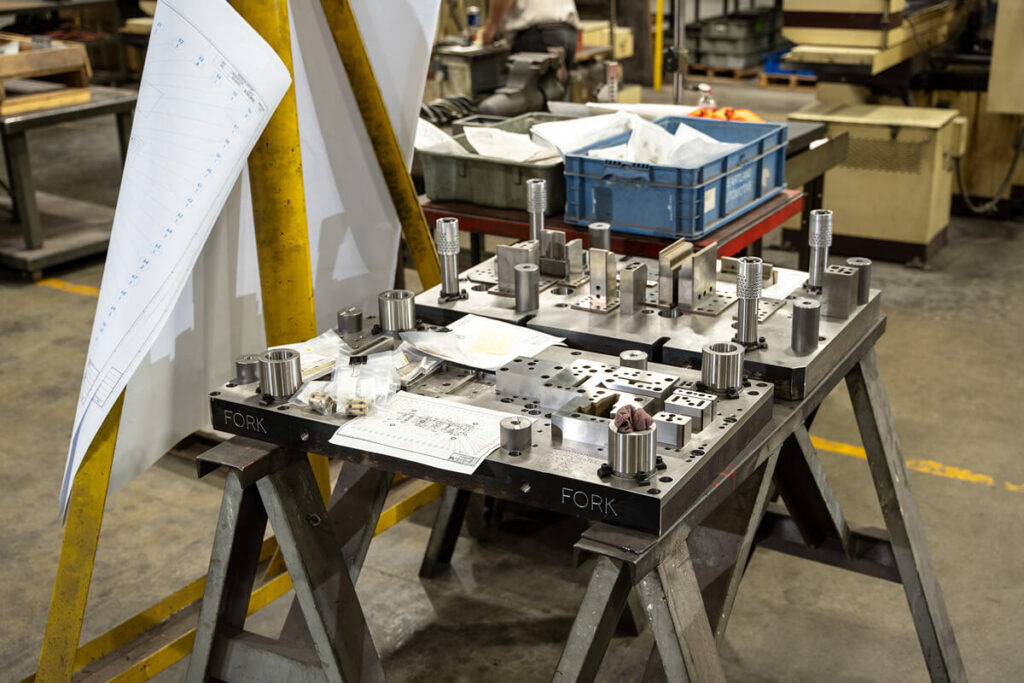

Monti Inc. has an expert team of Tool and Die Technicians who specialize in the design and build of custom tooling for our Stamping Department. Production dies are justified when manufacturing volumes are high, there are tight tolerances that need to be maintained or the part has complex features that require the advantages inherent in hard tooling. After thorough discussions, a die is designed with state-of-the-art software in which drastically reduces the time requirements and allows us to download machining programs directly to our CNC Mills and Wire EDM machines. After the die is built, sample parts are run for our Quality Department to conduct a PPAPs to ensure compliance to customer prints, only when parts are approved by QC and the customer, do we run production.

Die Design & Build Capabilities Include:

- Able to rapidly design tooling utilizing Die Design software

- Able to build simple low volume or complex progressive dies

- Able to run dies on 45 to 400 ton presses (15 total).

- Able to maintain and repair tooling on-site.